Introduction Technology Introduction Technology |

|

|

|

|

|

|

|

|

Manufactured Product Manufactured Product |

|

|

|

|

|

> Technology > Pellet fuel |

|

|

|

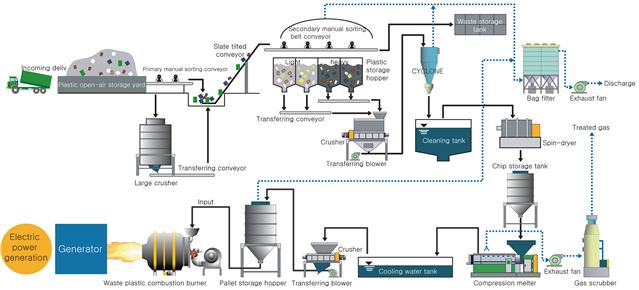

This technology makes use of heat generated by using and combusting pellet fuel made from melting nonrenewable high-caloric waste plastic as a fuel of the pellet combustion burner.

Form of technologies

Drum-rotation melting method

Principle of technologies

- After pellet is made by melting crushed waste plastic, the pellet is combusted at the temperature of 1,000~1,300℃ inside the combustion burner in the processes of liquefaction -> evaporation -> ignition.

※ Pellet fuel

- It is a fuel of a certain size made with the process of extrusion molding of soft plastic such as LDPE and PS.

- It is a fuel of a certain size made with the process of crushing of hard plastic such as PETE, HEPE, and PP.

○ Note) Analysis results of Korea Testing Laboratory

| Division

| Caloric value

| Division

| Proportion of ingredients

|

| Drying caloric value |

10,915.1kcal/kg

| Moisture

| 0.33%

|

| Higher caloric value |

10,897.1kcal/kg

| Combustiblecomponent

| 98.67%

|

| Lower caloric value |

10,092.0kcal/kg

| Ash content

| 1.00%

|

Technology applications

Electric power generation by a pellet combustion burner

Characteristics of technologies

- Automation

- Automation of fuel supply and operation

- Perfect combustion

- Steps of liquefaction -> Evaporation and ignition -> perfect combustion

- Suppression of generation of secondary pollutants (Dioxine, hydride, sulfur oxides, and so on)

- Compatibility

- It is possible to use it mixed with diesel and kerosene. (Thermal efficiency is over 90%)

- It is possible to automatically change when an error occurs while using pellet fuel.

- Resource recycling system

- Substitute for fossil fuel

- High economic feasibility through CDM business

- Making profits through the recycling of waste plastic

Drive Image

|

|

|

|