Introduction Technology Introduction Technology |

|

|

|

|

|

|

|

|

Manufactured Product Manufactured Product |

|

|

|

|

|

> Technology > Drying carbonization |

|

|

|

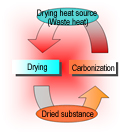

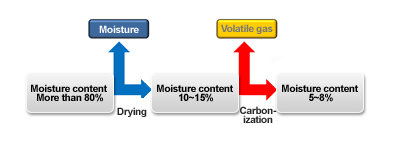

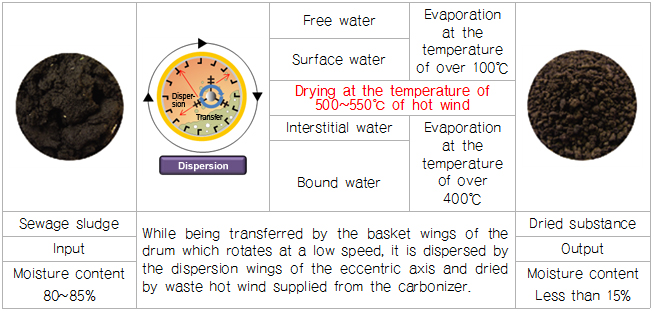

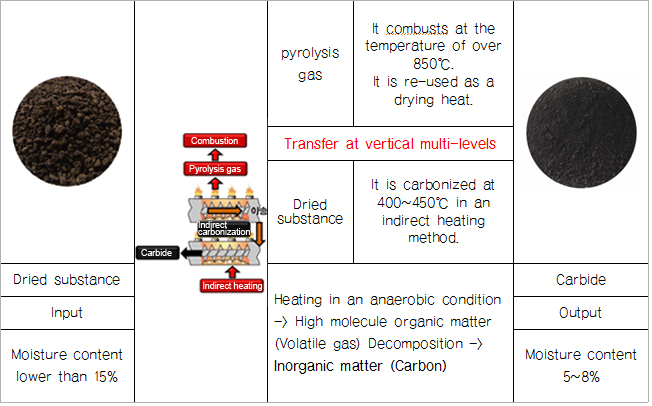

The waste is put into the rotary kiln drier where an eccentric axis rotates with the use of waste heat as a heat source, generated by burning pyrolysis gas at the temperature of more than 850℃, which is created in the carbonization treatment process. This waste is dried to the moisture content of lower than 15% and then carbonized at the temperature of 450~550℃ in a indirect heating method while going through the carbonizer where a screw conveyor is vertically installed at multi-levels.

Form of technology

- Drier : Co-current flow-type rotary kiln direct drying method

- Carbonizer: Vertical multi-level continuous indirect carbonizing method with a screw conveyor installed

Principle of technologies

Drying

|

|

|

|

- Continuous rotation stirring transfer-type hot wind drier by a rotary kiln method

- It can be dired to the moisture content of 10~15% within a short time of 20~40 min.

- Rotating at a low speed of about 5.3rpm inside the hot wind drier, the basket wings transfer the input raw materials and the dispersion wings of the eccentric axis inside the drum disperse the input waste.

- As food waste is dried by the hot wind of pyrolysis gas discharged from the carbonizer flowing into the drier,auxiliary fuel is not required additionally.

|

|

|

|

|

Carbonization

Characteristics of technologies

- Treatment efficiency

- Continuous treatment process in a continuous drying & carbonization method

- Treatment time: Drying: 20~40min / Carbonization: 10~20min

- Final moisture content: Dried substance: Less than 10~15% / Carbide: 5~8%

- Deduction rate: Drying: 70% / Carbonization: 90%

- Economic System

- As a resource circulation-type system, the volatile gas generated from the pyrolysis process ia re-combusted

and transferred to the drying system to be used as a heat source. So, auxiliary fuel is not needed additionally,

thus reducing the operation costs.

- Environment-friendly system

- It suppresses the generation of dioxine in an indirect carbonization method in an anaerobic or low-oxygen state.

- It suppresses the generation of odor with the combustion of volatile gas.

- Treatment of various organic wastes

- It can treat various organic wastes such as sewage sludge and food waste.

- Compact structure

- As a vertical multi-level type, it can minimize the area for installation.

- Recycling of by-product

- It can be re-used as a soil improvement agent, red-tide remover and compost.

- Energy fuel products (Thermal power plant, Cement manufacturer)

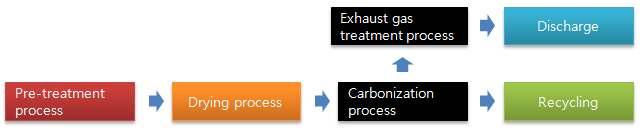

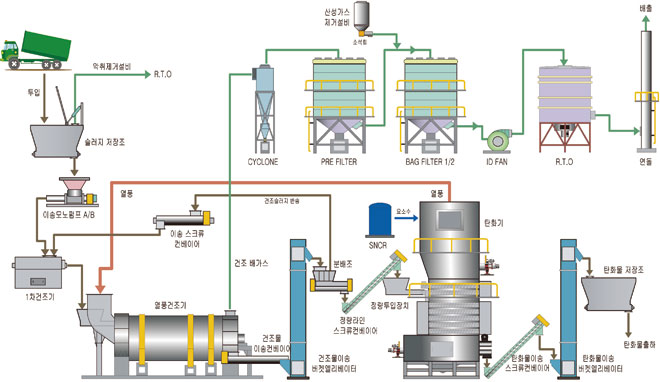

Whole treatment process

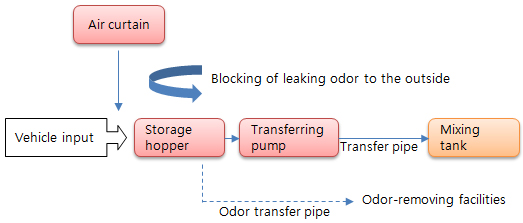

Pre-treatment process

|

|

| Sludge input |

|

| Sludge transferring pump

|

- The waste is put into the storage hopper and the input organic waste is transferred by the transferring pump to the

stage of drying process through the transfer pipe.

The odor, generated when the waste is input, is blocked from going

out by the air curtain, and the odor inside is removed by the odor-removing facilities.

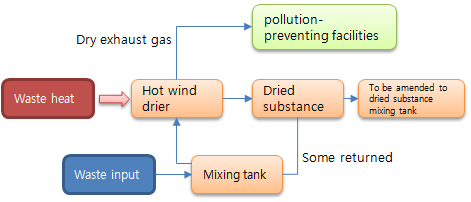

Drying process

|

|

| Hot wind drier |

|

Mixing device of

dried substances

|

- The waste transferred from the pre-treatment process is mixed with some of the dried substances returned at the stage prior to the carbonization process. And they go through the drying stage and the exhaust gas generated from the drying process is transferred to the pollution-preventing facilities. As a heat source, the waste hot wind (폐열풍) is used for drying after transferring it to the first dryer and the hot winf drier. So, no auxiliary fuel is required additionally.

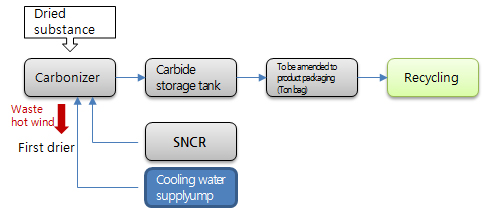

Carbonization process

|

|

| Carbonizer |

|

| Carbide(탄화물) delivery

|

- The required amount of dried substance goes through the vertical multi-level screw conveyor of the carbonizer and is carbonized indirectly in the lower (primary) combustion chamber. The pyrolysis gas generated in the carbonization process is combusted in the upper (secondary) combustion chamber and re-used as drying heat source (waste hot wind).

- The nitrogen oxide (NOx) generated in the pyrolysis process is absorbed and removed with the use of urea aqueous solution, and the carbide is re-used as a fuel.

- Characteristics of carbide

- It is chemically stable, harmless, and odorless. And it is possible to store it for a long time as there

is no elution of heavy metal.

- High caloric value: 1,500~3,500kcal/kg

- Its absorptive power is very strong as its specific surface area (percentage of voids) is big.

- Use of carbide

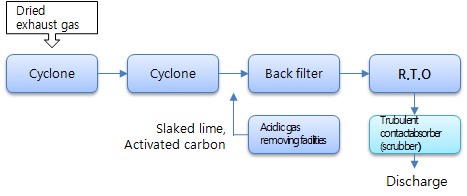

pollution-preventing facilities

|

|

|

| pollution-preventing facilities

|

- It eliminates particulates generated in the drying process through cyclones, prefilters, and back filters and the regenerative thermal oxidizer (RTO) and the water-sprinkling type dust collector remove and discharge VOCs to the atmosphere.

- With the use of slaked lime and activated carbon, the acidic gas removing facilities absorb and remove acidic gas (SOx, HCl, and so on) inside the dried exhaust gas.

process drawing

|

|

|

|